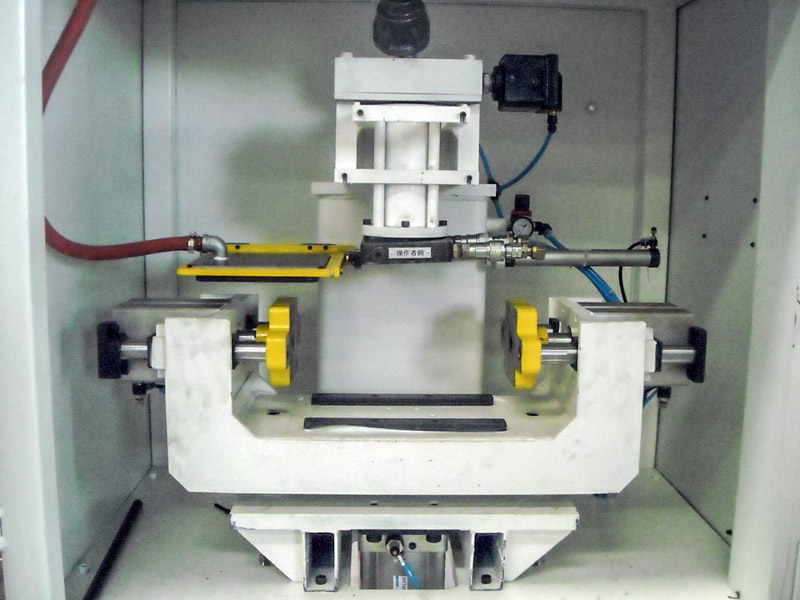

In addition to our standard core machine series, we provide a range of customized core machines for your specific needs. Have a look through our gallery at some examples of the non-series machinery we can offer where necessary for different processes, including: Coldbox (Isocure, S02, C02), Hotbox/Shell and Inorganic.

de

de en

en